30 Second Summary

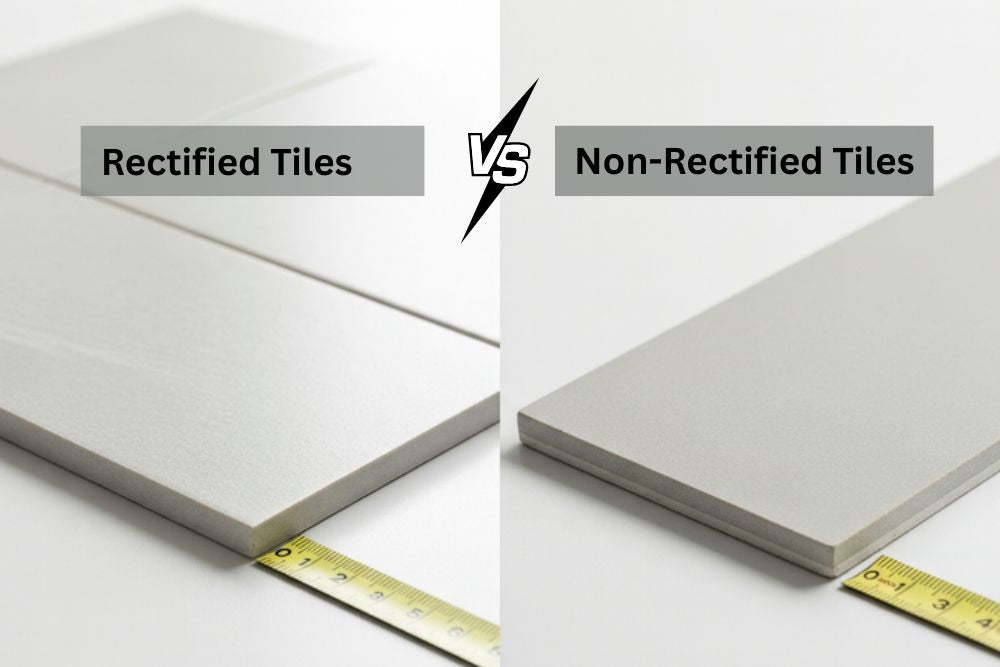

- When comparing rectified vs non-rectified tile, the main difference lies in the edges: Rectified tiles are machine-cut for perfect uniformity and ultra-thin grout lines, making them ideal for sleek, modern spaces. Non-rectified tiles have slightly uneven, natural edges for a warmer, rustic charm.

- Rectified tiles cost more, require precise installation, and suit large-format layouts. Non-rectified tiles are more affordable, easier to install, and better for traditional designs. Your choice comes down to style, budget, and installation needs. Additionally, glass tiles can be used in both styles, adding a unique, reflective surface that enhances any room’s light and ambiance. Your choice depends on style preference, budget, and subfloor condition.

Introduction

Picture this: you’ve finally decided to renovate your bathroom. You’ve spent hours on Pinterest, chosen a beautiful porcelain tile, and are ready to order. Then your contractor asks, “Do you want rectified or non-rectified tiles?” You freeze. Is this a trick question?

Tile terminology can feel overwhelming, but understanding the difference between rectified tile vs non rectified tile is crucial if you want the right look and performance for your space. The wrong choice could lead to mismatched aesthetics, difficult cleaning, or installation headaches.

This guide will explain what are rectified tiles, what are non-rectified tiles, and how to decide between them. You’ll learn about manufacturing processes, visual differences, cost implications, installation requirements, and rectified tile pros and cons so you can make an informed decision for your next project.

Key Takeaways

- Rectified Tile – Machine-cut edges for perfect uniformity; allows for ultra-thin grout lines (as little as 1/16"); ideal for modern, seamless designs.

- Non-Rectified Tile – Slightly uneven, natural edges; requires wider grout lines; perfect for rustic or traditional looks.

- Main Difference – Edge precision: rectified = sharp and square; non-rectified = slightly rounded.

- Cost – Rectified tiles are generally more expensive due to extra processing.

- Installation – Rectified tiles require a perfectly level subfloor; non-rectified tiles are more forgiving.

What Are Rectified Tiles?

The Manufacturing Process: How Rectified Tiles Are Made

Rectified tiles begin their journey much like any other ceramic or porcelain tile; with a blend of carefully measured raw materials such as clay, feldspar, silica, and other minerals. These ingredients are mixed together, often in a wet slurry form, to achieve the right consistency and composition. The mixture is then spray-dried into a fine powder that’s ready for pressing.

Once the material is prepared, it’s fed into molds and hydraulically pressed under extremely high pressure. This pressing process not only shapes the tile but also compacts the raw material to make it dense and durable. For porcelain, the pressure and density are even higher than for ceramic, giving it superior hardness and water resistance.

At this stage, the pressed “green” tiles (unfired tiles) are placed into a kiln, a massive, high-temperature oven that can reach temperatures exceeding 1,200°C (2,192°F). This firing stage transforms the clay body into a solid, vitrified structure. Glazed tiles will have their decorative surface applied before or during firing, while unglazed tiles retain their natural finish.

Now, here’s where rectified tiles diverge from their non-rectified counterparts. After firing, all tiles, regardless of type, shrink slightly due to the loss of moisture and structural changes in the clay body. However, this shrinkage is not perfectly uniform. Some tiles might end up a fraction of a millimeter longer or shorter than others. With non-rectified tiles, this variation is accepted and even embraced as part of their charm.

Rectified tiles, however, go through an additional, highly precise post-firing process. Once cooled, they are placed on specialized machinery equipped with diamond-tipped saw blades or, in some cases, high-pressure waterjet systems. These machines trim the edges of each tile with microscopic accuracy, often within a tolerance of ±0.25 mm.

This trimming ensures that:

- Every tile is identical in size – crucial for tight grout joints.

- Edges are perfectly square – eliminating the natural rounding caused by kiln shrinkage.

- Large-format layouts remain consistent – avoiding joint misalignments that can be noticeable over a large floor or wall.

In manufacturing facilities, this rectification process is often done in batches to tile maintenance consistency across a production run. Quality control teams measure samples with precision instruments, checking for both size uniformity and edge squareness.

In today's market, large-format tiles (24x24 inches or larger) are in high demand for these applications, offering a seamless look with minimal grout lines. However, their installation requires perfectly leveled subfloors, often achieved with self-leveling compounds, and the use of advanced leveling systems to prevent lippage and ensure a flawless finish.

In short, the extra cutting and calibration step is what separates rectified from non-rectified tiles, both in look and installation requirements. While it adds to the production cost, it’s the key to achieving that ultra-modern, perfectly aligned tile layout that so many homeowners and designers love.

A Few question arises in one’s mind about the rectified tiles like answers to which are below:

- How to Clean Rectified Tiles?

To clean rectified tiles, all you need is a pH-neutral cleaner, warm water, and a soft mop or cloth.

- Do You Need Special Tools to Install Rectified Tile?

Yes, installing rectified tiles does require specialized tools. A wet saw with a diamond blade is essential for making clean, precise cuts.

- What Are the Advantages of Non-Rectified Tiles?

The main advantages of non-rectified tiles include their flexibility during installation.

- Can You Use Rectified Tiles on Walls?

Yes, rectified tiles can definitely be used on walls. The precise, uniform edges of rectified porcelain tiles make them ideal for wall installations where a seamless look is desired.

Characteristics of Rectified Tile

- Perfectly Straight Edges – Allows for tight, consistent joints.

- Uniform Dimensions – Every tile is exactly the same size, eliminating visible irregularities.

- Minimal Grout Lines – As small as 1/16", creating a smooth, continuous look.

- Modern Appeal – Popular in minimalist, contemporary interiors.

-

Large-Format Friendly– Ideal for tiles 24x24 inches or larger, where precision matters and necessitates the use of advanced leveling systems and digital measurement tools for seamless installations in open-plan spaces.

What Are Non-Rectified Tiles?

The Traditional Approach: How Non-Rectified Tiles Are Made

The production of non-rectified tiles follows a more traditional and streamlined path compared to rectified tiles. The process begins with the same fundamental ingredients: clay, feldspar, quartz, and other mineral additives, which are carefully blended to achieve the desired strength, texture, and color. These raw materials are milled into a fine slurry or powder and then spray-dried into a uniform granulate, ready for shaping.

Once prepared, the granulate is fed into precision molds and hydraulically pressed to form the tile body. This pressing process shapes the tile and gives it its basic edges and surface profile. Unlike rectified tiles, which are destined for post-firing trimming, non-rectified tiles are designed to retain the natural shape they develop during the firing process.

After pressing, the tiles may be coated with glaze; either a single color, a pattern, or a textured finish. For non-rectified ceramic tile, glazing is common because it allows for decorative designs and protective surfaces. For porcelain varieties, glazing is optional; some are left unglazed to showcase the natural, through-body coloration.

The next step is firing in a roller kiln or tunnel kiln at extremely high temperatures; often between 1,050°C (1,920°F) and 1,250°C (2,280°F), depending on the tile type. During firing, two important changes occur:

- Vitrification – The tile becomes hard, dense, and water-resistant.

- Shrinkage – The clay body contracts as moisture is driven off and the minerals fuse together.

Here’s the key difference from rectified tiles: after firing, non-rectified tiles are not mechanically cut to exact dimensions. Instead, they are sorted and graded based on the size they naturally become in the kiln. This means there are tiny dimensional variations from one tile to the next; often fractions of a millimeter, but still enough to matter when laying tiles edge-to-edge.

The edges of non-rectified tiles are slightly rounded due to the softening effect of firing. This rounded profile is not a manufacturing defect; it’s an intentional characteristic that makes them easier to handle and install. Because the edges are not razor-sharp, they are less prone to chipping during transport and installation.

From an installer’s perspective, these small variations and rounded edges offer a significant advantage: they allow for wider grout joints; typically 1/8 inch (3 mm) or more. These joints help mask slight size differences and alignment issues, which is especially beneficial in:

- Older homes with uneven subfloors or walls.

- DIY-friendly projects, where ultra-precise alignment may be challenging.

-

Rustic or traditional designs, where the charm comes from visible grout lines and a handcrafted feel.

Once fired, cooled, and inspected, non-rectified tiles are packaged and shipped without any edge modification. This approach saves time, reduces manufacturing costs, and preserves the natural, slightly imperfect look that many homeowners and designers value.

In essence, non-rectified tiles represent the classic way tiles have been made for centuries, embracing slight variations, softer edges, and visible grout lines as part of their aesthetic identity. While they may lack the precision of rectified tiles, they make up for it in warmth, character, and installation flexibility.

Are rectified tiles more expensive? Yes, rectified tiles tend to be pricier because of the post-firing cutting process that ensures precise, uniform edges. Non-rectified tiles, however, retain their natural variations, making them more affordable and easier to install.

Characteristics of Non-Rectified Tile

- Slightly Uneven Edges – Gives a softer, handmade look.

- Natural Variations – Each tile has tiny size differences, adding to rustic charm.

- Wider Grout Joints – Typically 1/8" or more, making size variation less noticeable.

- Traditional Appeal – Perfect for farmhouse, Mediterranean, and vintage-inspired spaces.

What is the difference between rectified and non-rectified tiles? Let’s see in the comparison table below for better understanding:

Rectified vs. Non-Rectified Tile: A Head-to-Head Comparison

|

Feature |

Rectified Tile |

Non-Rectified Tile |

|

Edges |

Sharp, 90-degree angles |

Slightly rounded, natural |

|

Grout Lines |

1/16"–1/8" |

1/8" or more |

|

Look & Feel |

Modern, seamless, precise |

Rustic, traditional, organic |

|

Installation |

Requires flat subfloor and precision |

More forgiving of imperfections |

|

Cost |

Generally higher |

Generally lower |

|

Best For |

Large-format tiles, contemporary interiors |

Rustic, farmhouse, traditional styles |

If you’re deciding between rectified vs non rectified wood look tile, the same edge differences apply. Rectified wood-look planks give a tight, continuous “hardwood floor” appearance with minimal grout, while non-rectified wood-look planks highlight individual boards and suit rustic or farmhouse interiors.

Pros and Cons: Which Tile is Right for You?

Rectified Tile Pros and Cons

Pros:

- Minimal Grout Lines – Sleek, seamless surfaces are easier to clean.

- Modern Aesthetic – Sharp lines work perfectly in contemporary designs.

- Consistency – Uniform sizing ensures a precise layout.

Cons:

- Higher Price Point – Additional cutting adds manufacturing costs.

- Installation Demands – Requires an absolutely level subfloor and a skilled installer.

-

Risk of Lippage– Any unevenness can cause edges to stick up, but modern tile leveling systems and precision alignment tools significantly reduce this risk for a professional outcome.

Non-Rectified Tile Pros and Cons

Pros:

- Easier Installation – Can hide minor subfloor imperfections.

- Lower Cost – No extra cutting process.

- Warm, Character-Rich Look – Perfect for traditional or rustic designs.

Cons:

- Wider Grout Lines – Can trap dirt and require more cleaning.

- Less Seamless Look – Visible joints may not suit minimalist tastes.

Beyond edge treatment, modern tile innovations include high-tech features such as built-in LED lighting, antibacterial properties, and compatibility with radiant heating systems. These advancements are trending in residential and hospitality sectors, adding both functionality and aesthetic appeal to tile installations.

FAQs

Do I have to grout rectified tiles?

Yes, all tile needs grout to accommodate movement and prevent chipping. However, with rectified tiles, you can achieve a much thinner grout line.

Are rectified tiles harder to install?

Yes. Precision edges mean there’s no room to hide uneven surfaces. Installers increasingly rely on advanced clip-and-wedge or screw-based leveling systems, combined with laser levels and digital layout apps, to prevent lippage and ensure perfect alignment, especially with large-format tiles.

Why are rectified tiles more expensive?

The rectified vs non rectified porcelain tile price gap comes from the extra cutting and grinding process after firing, plus stricter quality control.

What type of grout should I use for rectified tiles?

Unsanded grout is typically recommended for the very thin grout lines used with rectified tiles. Grout spacing joints and prevent shifting during tile installation.

Conclusion

When it comes to rectified vs non rectified tile, the decision boils down to style, budget, and installation.

- Choose rectified porcelain tile if you want a precise, seamless surface.

- Choose non-rectified ceramic tile if you prefer a relaxed, traditional aesthetic.

Find the perfect finish for your project by exploring the extensive tile collections at MOSAICENTER. For expert guidance, contact our design specialists for a personalized consultation today.

Halil I Oguz

At Mosaicenter's, Halil I Oguz brings a unique blend of strategic insight and creative flair to our digital experience. As our dedicated Content Strategist, he masterfully curates the online journey, allowing the inherent quality and design artistry of our premium tiles to truly shine.

From showcasing the intricate patterns of our mosaics to detailing the robust, scratch-resistant and water-resistant finishes of our porcelain and natural stone, Halil crafts content that is both informative and deeply engaging.

His work empowers Mosaicenter's clients to confidently select from our extensive range, helping them transform spaces with tiles that reflect both enduring style and practical excellence.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.